Engineering

Het begint bij expertise in engineering

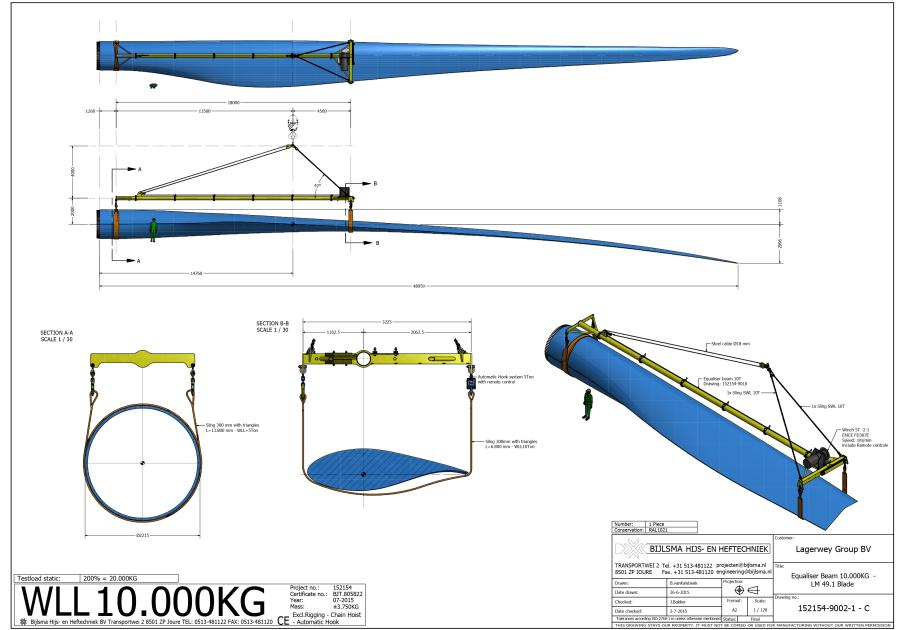

Op zoek naar een slimme hijsoplossing?Soms speelt een standaard hijs- of hefinstallatie niet voldoende in op het gestelde doel van de toepassing. In die gevallen denken onze engineers mee over een oplossing op maat. Kis Kraanbouw heeft een eigen engineering-afdeling, bestaande uit mechanische- en electro-engineers. Zij ontwikkelen en programmeren onderdelen voor de besturing en bediening van de kraaninstallatie..

Mechanische engineers

Ontwikkeling van kraaninstallaties op maat door deOnze mechanische engineers bedenken, ontwerpen, analyseren en verbeteren kraaninstallaties. Zij hebben een achtergrond in de werktuigbouwkunde, passen de nieuwste technieken toe en houden zich bezig met:

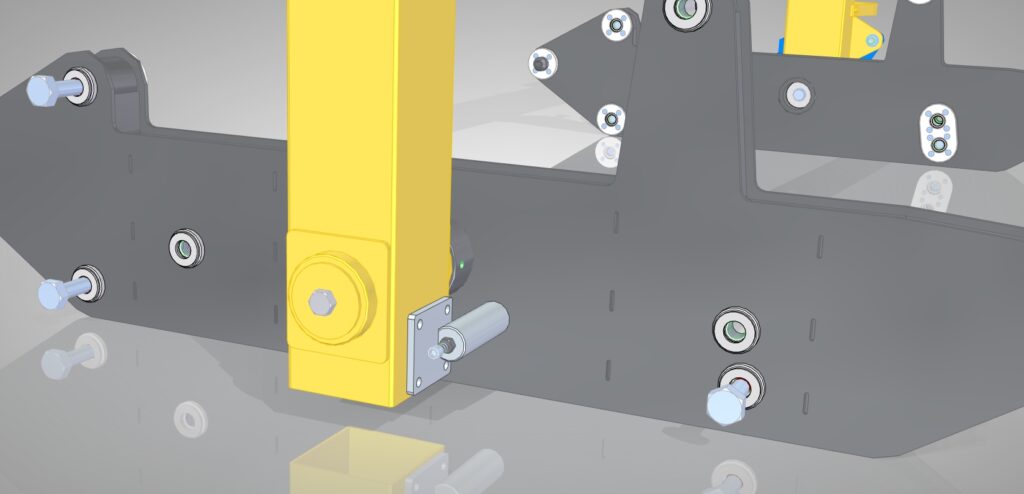

- Schetsen, tekeningen en ontwerpen maken in Inventor

- Vermoeidheidsberekeningen opstellen

- De FEM-klasse & metaalvermoeiing berekenen

- Risico-inventarisatie in kaart brengen en vastleggen

- Procesverbetering en efficiency realiseren met het ontwerp

- De toegevoegde waarde van de hijsinstallatie vergroten

- Over componenten adviseren die bijdragen aan een proces

- Uitgebreide gebruikersinstructies, voorschriften en onderhoudsschema’s maken

- Veiligheid van de installatie volgens de laatste normeringen waarborgen

Samen met klanten wordt de risico-inventarisatie opgesteld. Wij weten wat de risico’s zijn van de technische installatie, maar krijgen pas een volledig beeld als we ook het beoogd gebruik van de installatie hierin meenemen.

Electro-engineers

Toepassing van een elektrotechnische meerwaarde door deOnze electro-engineers ontwerpen, installeren, beheren en verbeteren de elektrotechnische kant van installaties. Zij zijn opgeleid in de Elektrotechniek of Electrial Engineering, zijn volledig op de hoogte van innovatieve softwareontwikkeling en programmeren in het TIA Portal voor:

- Toepassing van fail safe technologie

- Integratie van PLC-besturing

- Mogelijkheden rondom data logging en monitoring

- Correlaties tussen data en output

- Uitvoering van (preventief) onderhoud aan installaties

- Procesverbetering en efficiency dankzij de programmering

- Installatie en aanpassing van (nieuwe) besturingssystemen

- Koppeling van de PLC met interne systemen

- Advisering aan klanten over elektrotechnische vraagstukken

De afgelopen jaren heeft Kis Kraanbouw ingezet op vernieuwende softwareontwikkeling. We hebben daarin veel projecten opgepakt, zoals bijvoorbeeld bij Scania. Geautomatiseerde installaties worden in onze eigen werkplaats opgebouwd. Op die manier kunnen de engineers voorprogrammeren en uitvoerig testen. Het resultaat is dat wij de installatie direct gebruiksklaar opleveren en op locatie plaatsen.

Waar wij voor staan

- Gericht advies voor specifieke hijsvraagstukken

- Ontwerp op maat door onze ervaren engineers

- Merkonafhankelijke uitwerking zonder contractuele verplichtingen

- Veiligheid voorop met machinerichtlijnen (NEN), ISO 9001 en EN 1090 Welding